QNAP® Copper Naphthenate is a copper naphthenate solution registered with the EPA as a general-use wood preservative. This preservative delivers long-lasting protection for treated wood while requiring no special equipment to apply. Once treated, wood is considered non-hazardous waste, meaning it can be recycled or even used for energy recovery at the end of its life cycle.

WHAT YOU SHOULD KNOW ABOUT QNAP

Green Solutions for Railroad Ties

QNAP is an 8% oil-borne copper naphthenate solution registered with the EPA as a general-use wood preservative. It’s formulated from recycled copper and by-products of oil refining, making it a sustainable option right from the start*. This preservative delivers long-lasting protection for treated wood while requiring no special equipment to apply. Once treated, wood is considered non-hazardous waste, meaning it can be recycled or even used for energy recovery at the end of its life cycle.

*in approved boilers

- AWPA U1-11 Section 6C Standards & P36

- Non-Conductive/Non-Corrosive

- Efficacy Equal to Other Oil-Borne/Oil Type Preservatives

- Less Drippage/Bleeding in Commercial Experience

- Cleaner Handling Characteristics

- Allows Recycling and Energy Recovery

- Same Lubricating Properties as Other Oil-Borne Preservatives

- Compatible with Cellutreat Borate Pretreatment

- Cost Effective, Non-Restricted Use Pesticide

Minimum Retention for Rairoad Ties in lb/cu ft of Cu

| AWPA | Oak and Hickory | All Others |

| UC 4A,4B,4C | 0.055 or refusal | 0.06 |

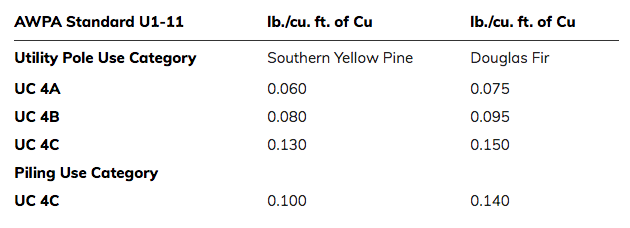

QNAP provides benefits to the pole and piling Industries

QNAP is an 8% oil-borne copper naphthenate solution registered with the EPA as a general-use wood preservative. It’s formulated from recycled copper and by-products of oil refining, making it a sustainable option right from the start*. This preservative delivers long-lasting protection for treated wood while requiring no special equipment to apply. Once treated, wood is considered non-hazardous waste, meaning it can be recycled or even used for energy recovery at the end of its life cycle.

*in approved boilers

- AWPA U1-11 Section 6D & P36 Standards

- Disposal Options Include:

- Recycle and Re-Use

- Use as an Energy Source

- Disposal in Approved Landfills

- The Best Gaff Penetration of All Commercial Pole Preservatives Tested

- Non-Conductive/Non-Corrosive

- Reduced After Glow Combustion

- Poles Don’t Become Brittle

- Less Drippage and Bleeding in Commercial Experience

- Clean Handling Characteristics

- Compatible with Cellutreat Borate Pretreatment

The Green Solution for preserving timber and lumber

QNAP oil borne copper naphthenate concentrate is the perfect preservative, providing both excellent wood decay protection and the superior waterproofing qualities of an oil born preservative. QNAP treatments result in preserved wood that is cleaner to the touch, with minimal excess preservative coming in contact with the environment. QNAP is the green choice in copper preservatives because it is not a restricted use pesticide. With durability better than other oil-borne preservatives, it is fast becoming the first choice for bridge timbers, barn timbers, glulam beams, salt storage domes, protector boards and highway railings.

The Green Preservative

QNAP copper naphthenate is the perfect solution for treating fence posts, vineyard posts, split rails and landscape timbers. Treatments can be made using dip treatments, pressure treatments or thermal butt treatment.

Benefits of QNAP:

- Not a restricted use pesticide which means it can be applied by anyone.

- Easy to use with good penetration

- No corrosion

- Paintable and stainable

- Easy to nail and staple

- Reduces afterglow

- Clean handling characteristics

Professional Strength Wood Preserver

Copper Naphthenate is the best and most effective wood preservative available to contractors and do-it yourself consumers. It is perfect for use when wood products will be in contact with the ground and as an end cut treatment when you cut pressure treated wood.

Copper naphthenate is available at many building supply stores and hardware stores.

Section 7 of AWPA Standard M-4 from 2008 describes preservation systems for field treatment of wood:

"The appropriateness of the preservation system for field treatment shall be determined by the type of preservative originally used to protect the product and the availability of a field treatment preservative. Because many preservative products are not packaged and labeled for use by the general public, a system different from the original treatment may need to be utilized for field treatment. Users shall carefully read and follow the instructions and precautions listed on the product label when using these materials."

Copper Naphthenate preservatives containing a minimum of 2.0% copper metal are recommended for material originally treated with copper naphthenate, pentachlorophenol, creosote, creosote solution or waterborne preservatives. Use of copper naphthenate preservatives with a minimum of 1.0% copper metal is appropriate in those regions of the country where the higher concentration material is not readily available.

Inorganic Boron preservatives are limited to use in applications not in contact with the ground and continuously protected from liquid water. They may be used for field treatment of material originally treated with any waterborne treatment as long as this condition is met. Solutions shall have a minimum concentration of 1.5% (B2O3 basis).

QNAP1 - RTU Copper Naphthenate, Oil-based 1% Cu active

QNAP2 - RTU Copper Naphthenate, Oil-based 2% Cu active

QNAP1W - RTU Copper Naphthenate Water-based, 1% Cu active

PENASHIELD

Liquid DOT for end cut treatment of pressure treated wood used in the interior of structures. PenaShield can also be used as a general wood preservative outdoors if wood will be painted or stained and on any interior wood.